We Provides Linear Vibrator for Feeding Components for Subsequent Operations on Special Machines in Cosmetic, Electrical, Mechanical, Pharmaceutical, Bearing and Many other Industries. The Components can be Capsules and Electrical Connectors, Bearings as well as Heavy parts such as anchor bolts, Bearing races.

Vibrator Controllers / Regulators :

Every drive unit is supplied with a separate control regulator, which makes it possible to control the speed of the feeder infinitely. Standard units are suitable for electrical supply of 230 volts, 50 Hz and provided along with soft start controllers. In case of requirement, units suitable for 110 V / 60 Hz can also be offered.

Application

Linear Feeders are suitable for feeding components for subsequent operations on special machines in cosmetic, electrical, mechanical, pharmaceutical, optical, bearing and many other industries.

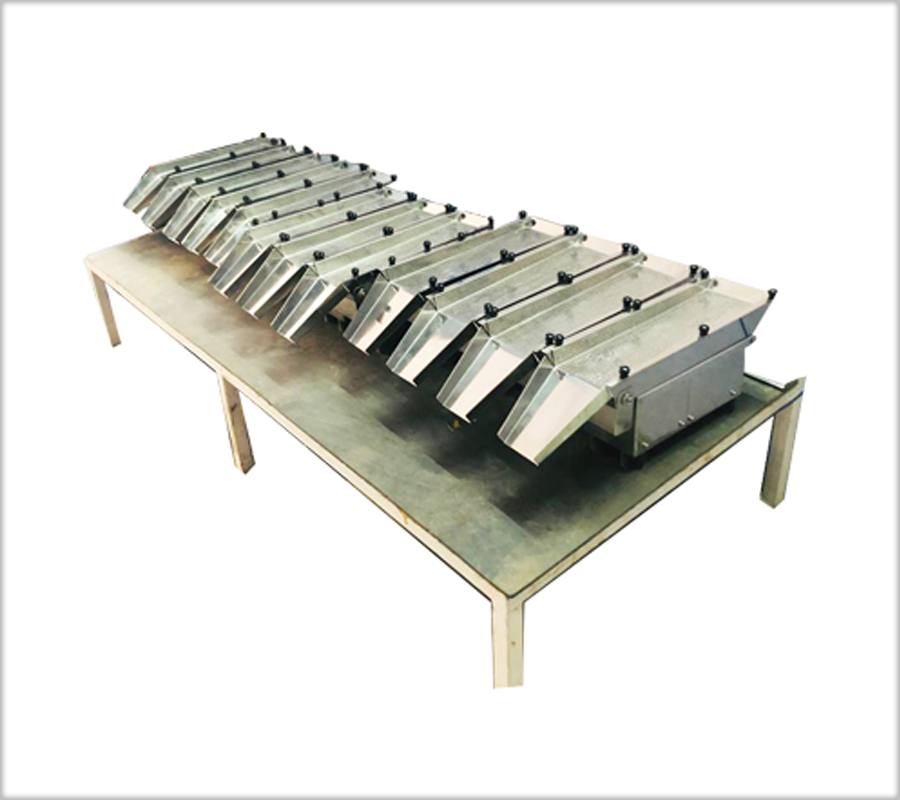

We are an Auto feeding system manufacturer and exporter of linear feeders, two-track linear feeders, single-track linear feeders, and aura feeding systems, with our headquarters in Ahmedabad.

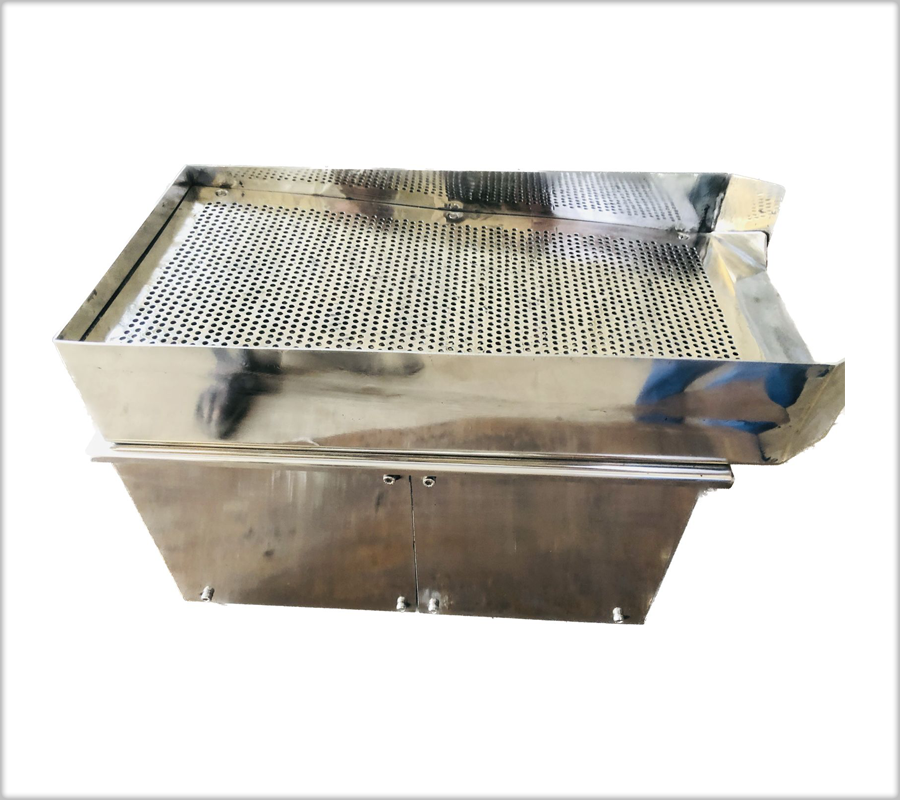

MJ Industry Feeding Systems is a market leader in providing high-quality Linear Vibratory Bowl feeders. This feeder is in high demand in the industry due to its extended operational life and easy operation. The offered feeder is made using high-quality components and cutting-edge technology in accordance with industry standards. Aside from that, our consumers may have the supplied feeder at a reasonable price.

Linear vibrator Feeders are used to feeding components for subsequent operations on special machines in the cosmetic, electrical, mechanical, pharmaceutical, and bearing industries, among others. Capsules and electrical connectors, as well as bearings, are examples as well heavy parts such as Anchor bolts, bearing races

What exactly is a linear feeder?

Aside from transit, linear vibrator bowl feeders can serve as buffers and accumulation lines. Even if their feeding is inadequate or irregular, the prior sorting installation can constantly supply component components for the subsequent processing step.

Furthermore, linear vibrator bowl feeders allow for lateral oscillation-free sorting (linear sorting lines). These sorting lines can also be built as multi-tracks to increase sorting efficiency. Parts that have been sorted are returned to the preceding feeding system through sorting hoppers, which are also actuated by the linear feeder.

Linear feeders can also be used to operate bulk hoppers, which are used to stack mass-produced parts. The benefit of these vibratory hoppers over conventional hopper systems is that they guarantee trouble-free material flow and allow for huge loading weights due to the way they are built.

RNA linear feeders have large feeding capabilities and perform well even on lengthy feeding lines and in harsh circumstances.

Automatic feeders

A feeding machine, also known as an automated feeder, is made up of four basic components: a feed container (hopper), a feed distribution mechanism, an electrical power source for the distribution mechanism, and a control unit for initiating and halting the distribution mechanism. The feed distribution system is the fundamental component that separates a linear vibrator bowl feeder manufacturer from a feed dispenser. The feeders are often mounted on a rack on the tank or cage, but they can alternatively be integrated into a buoy. When employing an automated feeder, the amount of feed that must be delivered during a specific time period is determined, and the distribution unit runs for the duration of that demand.

Automatic Feeding System

For years, MJ Industry has been a manufacturer of Automatic Feeding Systems in India. Our automated feeding system now allows fulfilling this goal without sacrificing any more of your valuable time.

Feeders for linear vibratory bowls

Linear Vibratory Bowl Feeders are the most advanced, dependable, and durable machines on the market today. RNA bowls gently feed and position your goods, ensuring a steady and correct flow of components into your manufacturing process. The demand for industrial electromagnetic vibrators has been increasing respectively.