Hopper (Or Storage Hopper)

The storage hopper is the storage area provided to backlog bulk parts prior to entering the feeder bowl. This hopper eliminates overloading or insufficient loads of parts, causing the bowl not to function as required. Feed rate from the hopper to a bowl is metered by a level control switch

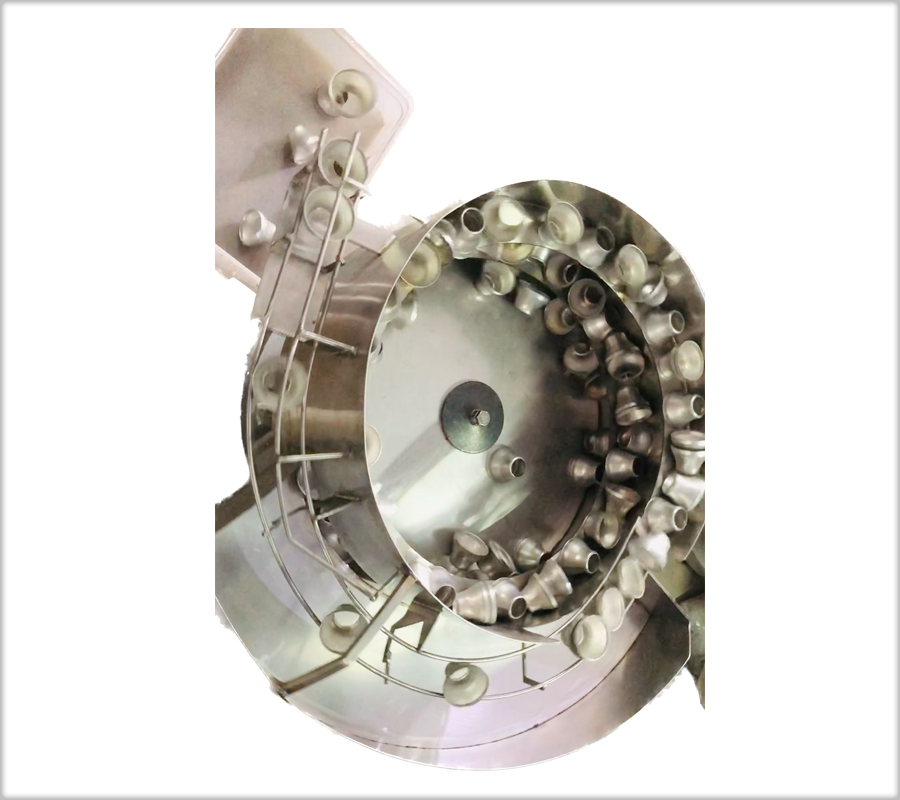

Basic Bowl

The band, bottom and track assembly prior to any tooling for a specific part. Basic bowls are not off-the-shelf standard items. They are individually designed and can be supplied for any profile of part up to approximately 5” long.

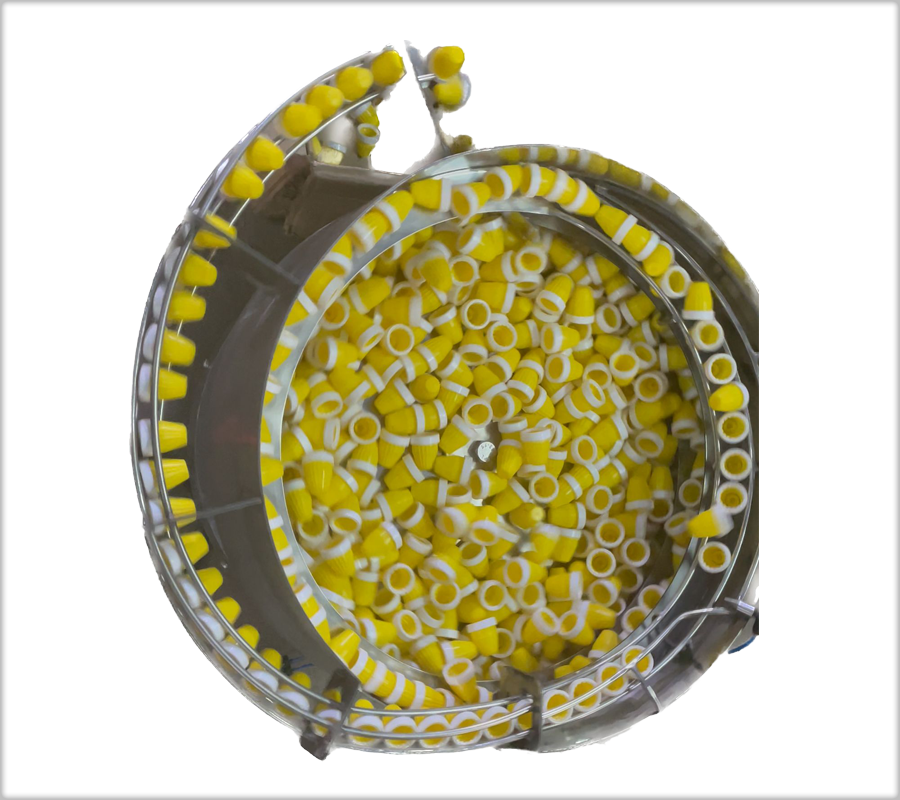

Feeder Bowl

The feeder bowl is the actual orienting and feeding device that orients the part to your machine requirements and is the heart of the system. The feeder bowl is always custom tooled to a specific part configuration. Feeder bowls are almost always round and constructed of stainless steel for long life.

Rate (Or Feed Rate)

The number of parts per minute, or per hour, which you require to meet your production requirements.

Orientation

Positioning of part in the attitude you desire for your operation.

Selector

An area of the system designed and custom fit to profile only the properly positioned part. Parts entering a selector which are not in the proper position are diverted out of the feed line.

Confinement

The fabrication installed to assure 100% control of the part after a selector ejects improperly positioned parts.

Discharge Of The Feeder Bowl

This is the last section of the bowl. In most cases, it is a straight exit that confines the parts after they are oriented.

Track Switch

A switch of any type which turns the feeder off whenever the tracking to the machine becomes full. The track switch also helps to eliminate wear, noise and jams within the feeder. Air, photo-electric, proximity and electro-mechanical track switches can be used.

Track Switch

We are a remarkable bowl feeder manufacturer based in Ahmedabad, India. We provide a broad selection of Electric Vibratory Bowl feeders. These items are offered in a variety of specifications to fulfill the needs of customers. When it comes to vibrating bowl feeders, experience is everything. In fact, understanding the tooling of a bowl feeder takes more than two years. In this regard, the marijuana sector is extremely well-positioned. Elscint’s workforce now has about 200 years of collective tooling expertise, ensuring that practically all sorts of components have been handled by its personnel at some point. Thus, the MJ industry has been servicing the global industry by supplying tiny part handling solutions such as vibratory bowl feeders, linear feeders, small parts conveyor feeders, rotary or centrifugal feeders, and so on.

Features

Feeders with Vibratory Bowls

Vibratory Bowl Feeders are the most advanced, dependable, and durable machines on the market today. RNA bowls gently feed and position your goods, ensuring a steady and correct flow of components into your manufacturing process.

Benefits

The most popular part of feeding equipment used to feed components in Industrial Assembly Automation Applications is a vibratory bowl feeder. Vibratory feeders are self-contained systems that include a specifically designed bowl feeder that orients the components, a vibrating driving unit to which the bowl feeder is attached, and a variable-amplitude control box.

Part feeding system

SDC’s manual loading of components is a part-feeding system that offers various advantages. Manually loading components is a cost-effective way to enter complicated parts with a high degree of unpredictability. Furthermore, the Cap feeding system is very adaptable and may be tailored to a wide range of applications. An operator would manually put components into fixtures or holders for the automated system in this sort of setup. The usage of an operator puts a person’s skills (e.g., flexibility, adaptability, critical thinking, etc.) to good use. Common applications include situations in which a client demands a limited volume of components or a low operating speed (perhaps for a test assembly). However, manually loading components can also be effective in a high-speed application.

Feeder rotary

When high-speed orientation and feeding of components are required, the only option is to use a Rotary bowl Feeder. These can assist in reaching speeds of up to 50 meters per minute.